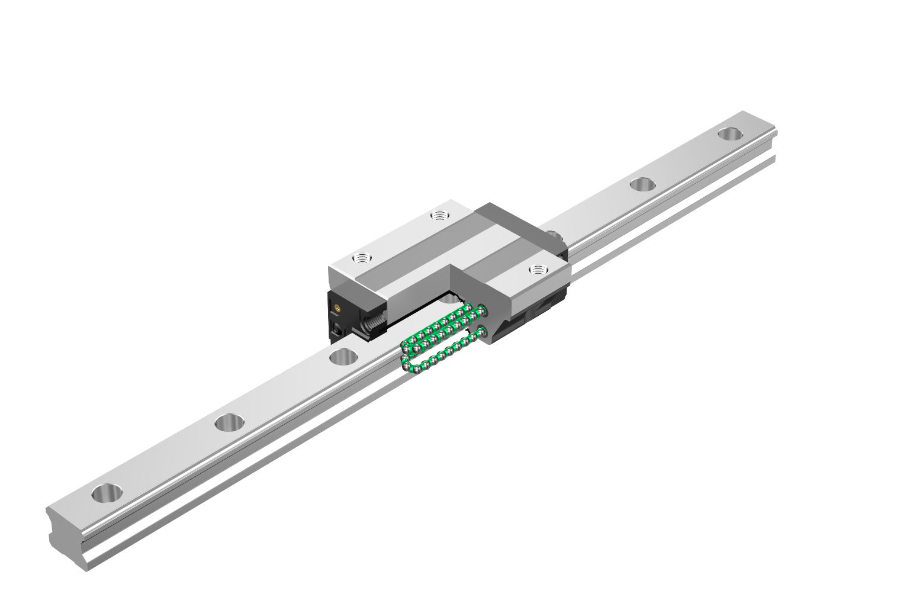

The Bearing cage LM Guide SHS features a highly rigid design, allowing it to produce precise and linear motion. All four rows of raceways are precision ground on an LM rail and an LM block to ensure a smooth ride for the balls. With the help of the LM block’s built-in ball cages and endplates, the balls can move freely. The hops in each row are set at a contact angle of 45 degrees to make the Bearing cage LM Guide SHS( รังลูกปืน LM Guide SHS, which is the term in Thai) usable in any orientation. It ensures that the rated loads delivered to the LM block are the same in all four directions (radial, reverse-radial, and lateral).

As a bonus, the LM block preloads in a way that optimizes its rigidity in all four dimensions while keeping the friction coefficient the same. Visit a reputed company when you need high-quality Caged Ball LM Guides for your manufacturing process.

History Of LM Guide

It was in 1944 when the first linear motion rolling guide, the ball bushing, was created in the United States. Balls are rolling elements in the ball bushing, sandwiched between a cylindrical shaft and a sleeve-type nut. They achieved Infinite linear motion because of the balls’ ability to recirculate in response to the nut’s movement.

Because the balls make point contact with the shaft and nut and the contact surface area is limited, the ball bushing has an insufficient load capacity. In addition, the moment (torque) acting on the shaft causes the nut to rotate, necessitating two or more poles to prevent the nut from deviating from the axis of travel; developing small machinery was complicated.

Advantages Of Bearing Cage LM Guide SHS

- Due to the reduced friction between the balls and the higher amount of grease retained, a longer service life and lubrication-free operation are possible.

- Because of the elimination of ball-on-ball collisions, a surprisingly pleasant running noise is produced.

- Moreover, as there is no friction between the balls, the temperature is kept low, and the speed is kept high.

- Lines of uniformly spaced balls circulating in the system ensure consistent rotation.

- Since there is no rubbing between the balls, Bearing cage LM Guide SHS retains the grease well and creates no dust.

Conclusion

Bearing cage LM Guide SHS is crucial to the smooth operation of machines because of the loads they sustain and the ease with which they direct linear motion. Machine tools and semiconductor fabrication equipment rely heavily on them since they are essential linear components. Trains, buses, automatic doors, earthquake protection systems, and other consumer applications have recently adopted their use.