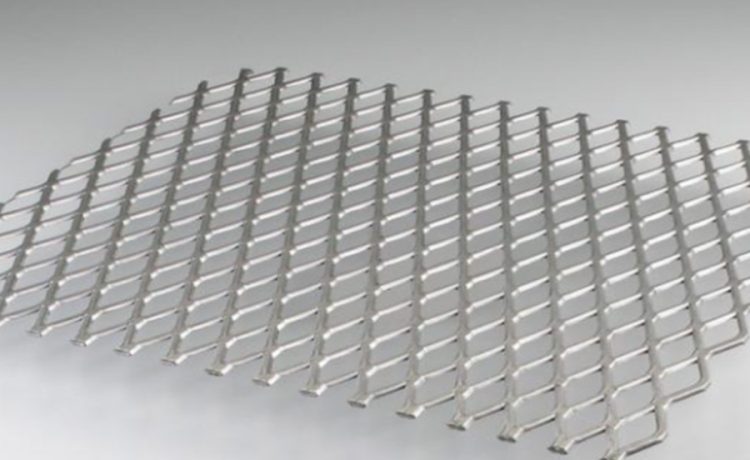

Think about the last time you stood before a really impressive modern building, maybe one with a shimmering, textured facade that seemed to breathe. Or perhaps you’ve safely leaned against a sturdy industrial catwalk, noticing the floor beneath you was both solid and full of holes. Chances are, you were looking right at an Expanded Metal Mesh without even knowing it. This isn’t your average woven wire, it’s something smarter. Imagine taking a single, solid sheet of metal—aluminum, stainless steel, galvanized steel—and with a precise, synchronized process, slitting and stretching it. This transformative act doesn’t remove any material, it magically turns that solid sheet into a coherent, diamond-patterned web. The result? A material that laughs in the face of a seeming paradox: achieving superior strength while delivering optimal airflow and visibility. It’s this unique duality that makes expanded metal mesh the unsung hero from factory floors to avant-garde architectural wonders. From the decorative aluminum panels on a chic building facade to the heavy-duty 4X8 sheets guarding a factory machine, this material solves problems we didn’t even know we had so elegantly.

The Anatomy of Strength: Why It Doesn’t Bend Under Pressure

So, how does a sheet full of holes end up being stronger than you’d think? The secret isn’t in adding more material, but in re-engineering what’s already there. The manufacturing process, where the metal is simultaneously slit and stretched, is key. Unlike punching holes out of a sheet (which removes material and creates potential weak points at the edges), the expanding process redistributes the metal into a continuous, integrated pattern.

This creates a structure where stress is distributed evenly across the entire sheet. Think of it like a suspension bridge. The strands of a bridge work together to carry a load, similarly, every strand in an Expanded Metal Mesh is part of a unified, load-bearing network. When pressure is applied, it’s not focused on one weak spot but shared across the diamond-shaped ligaments and bonds. This inherent design gives it remarkable rigidity and resistance to bending. That’s why you’ll find it underfoot on industrial platforms and walkways—it can support significant weight without permanent deformation. The strength is also “directionally tunable.” In a standard expanded metal sheet, the diamond pattern has a long way (the direction of the stretch) and a short way. It will naturally have greater strength in the long way, allowing engineers to orient the sheet based on the load requirements. This intelligent use of material is why a relatively lightweight expanded metal sheet can serve as a protective guard for heavy machinery or a robust security screen, providing safety without the visual bulk of a solid plate.

Furthermore, the choice of base metal multiplies this strength. A stainless steel expanded metal mesh brings corrosion resistance and high tensile strength to the table, perfect for harsh chemical environments or marine applications. An aluminum expanded metal sheet offers an excellent strength-to-weight ratio, ideal for architectural features where weight is a concern. This combination of intelligent design and material science is what delivers that promised superior strength. It’s not just strong for a mesh, it’s strong, period. Its durability is evident in applications like heavy-duty filtration screens that withstand constant pressure and impact, or in decorative metal mesh curtain walls on skyscrapers that must endure decades of wind, rain, and temperature changes.

The Art of the Breeze: Engineered Pathways for Air and Light

Now, let’s flip to the other side of its genius: its openness. The most obvious feature of any Expanded Metal Mesh is its pattern of openings. But these aren’t just random holes, they are precisely calculated apertures that create a clear, unobstructed pathway for air, light, sound, and even views. This is where the optimal airflow part of the promise comes to life.

In mechanical and industrial applications, this is critical. Equipment generates heat, and that heat needs to escape to prevent overheating and failure. A solid metal enclosure would trap that heat, while a loosely woven mesh might not provide enough protection. An expanded metal mesh screen is the perfect middle ground. It acts as a protective barrier that contains debris and prevents accidental contact with moving parts, while its open area—which can be customized from very fine to very large—allows hot air to convect out freely. This passive cooling can be enough to drastically extend the life of motors, generators, and electrical cabinets. The same principle applies to ventilation grilles and louver. The mesh allows for high-volume air intake and exhaust while filtering out larger particulates, making it a workhorse in HVAC systems and engine compartments.

But the airflow solution isn’t just physical, it’s visual and atmospheric. In architecture, this material transforms buildings from opaque boxes into dynamic, layered experiences. A decorative mesh curtain wall made from expanded metal wraps a building in a shimmering veil. From the inside, occupants enjoy diffused natural light and outward visibility, while from the outside, the building’s facade changes with the angle of the sun and the viewer’s position. This creates a “breathing” facade that provides solar shading (reducing cooling costs) without sacrificing light or the connection to the outdoors. The optimal airflow here is for people’s comfort and well-being. Similarly, using expanded metal ceiling panels in an interior space can help manage acoustics by breaking up sound waves, while maintaining an open, airy feel and allowing for air circulation from plenums above. It’s a solution that proves functionality and breathtaking beauty can come from the same sheet of metal.

Where Theory Meets Reality: Applications That Showcase the Dual Superpower

You can talk about strength and airflow all day, but seeing this material in action is where it all clicks. The provided content from Haopeng Metal showcases this perfect marriage perfectly across diverse fields.

In the commercial and cultural building sector, the application is transformative. For museums, theaters, and concert halls, a decorative mesh curtain wall does more than just cover the building. It “can show the artistic atmosphere and cultural connotation,” creating a striking first impression that hints at the creativity within. For high-end residential balconies or terraces, it provides privacy and safety without the closed-in feeling of solid walls, literally allowing the breeze and light to filter through. This is the ultimate demonstration of optimal airflow paired with aesthetic strength.

On the industrial side, the strength takes center stage. Think of an expanded metal walkway in a factory or on an oil rig. It provides a safe, slip-resistant surface (the raised strands offer natural traction) that doesn’t trap water, snow, or debris. Its open design allows light to pass through to levels below and prevents the buildup of dangerous gases. In automotive applications, like in car mufflers, specific perforated or expanded meshes are used internally to manage exhaust flow and dampen sound—a critical performance and environmental application where managing airflow under high heat and pressure is key.

The beauty of Expanded Metal Mesh is also in its adaptability, or as Haopeng puts it, “Customization.” You are not stuck with one standard diamond. The strand width (the metal “bone” of the diamond), the bond (where strands intersect), and the opening size (the LWD – Long Way of Diamond) can all be tailored. Need a fine mesh for a sieve or a filter with high open area for maximum flow? They can make it. Need an extra-heavy-duty pattern with flattened strands for a perfectly smooth industrial floor? That’s possible too. This ability to customize means the perfect balance between superior strength and optimal airflow can be dialed in for virtually any project, from a delicate decorative interior feature to a massive industrial filtration system.

Beyond the Basics: The Unsung Advantages

While strength and airflow are the headliners, Expanded Metal Mesh brings a full supporting cast of benefits to the job site. Its durability is legendary. Materials like stainless steel or aluminum offer exceptional resistance to rust and corrosion, meaning installations last for decades with minimal maintenance. This is a huge cost-saving advantage over materials that need frequent painting or replacement.

From a sustainability and cost perspective, the expanding process is incredibly material-efficient. Since no metal is removed (unlike punching or laser cutting), there’s virtually no waste. This makes it an economically and environmentally smart choice. You get more coverage and utility from a single sheet of raw metal. Furthermore, its lightweight nature (especially aluminum) reduces the structural load on buildings and cuts down on shipping and handling costs.

Finally, let’s not forget safety. The textured surface provides excellent slip resistance, a non-negotiable feature for flooring and stair treads in wet or oily environments. As a safety screen or guard, it contains sparks from welding or grinding, contains fragments from machinery, and protects workers while maintaining critical visibility and ventilation around equipment. It’s a material that literally safeguards people while it performs its primary job.

Conclusion

From the sleek facade of a cutting-edge cultural center to the gritty, reliable floor of a power plant, Expanded Metal Mesh proves that true innovation often lies in elegant simplicity. It masterfully solves the ancient engineering riddle of being both solid and open, strong and breathable. It doesn’t just find a compromise between strength and airflow, it excels at both simultaneously, thanks to its unique, waste-free manufacturing process. Whether you’re an architect designing the next landmark, an engineer solving a ventilation challenge, or a project manager sourcing safety materials, this is a solution that works harder and smarter. It’s more than just wire mesh, it’s a testament to how rethinking the very structure of a material can unlock a world of possibilities, letting air, light, and ideas flow freely, all while standing firm against whatever pressure comes its way.