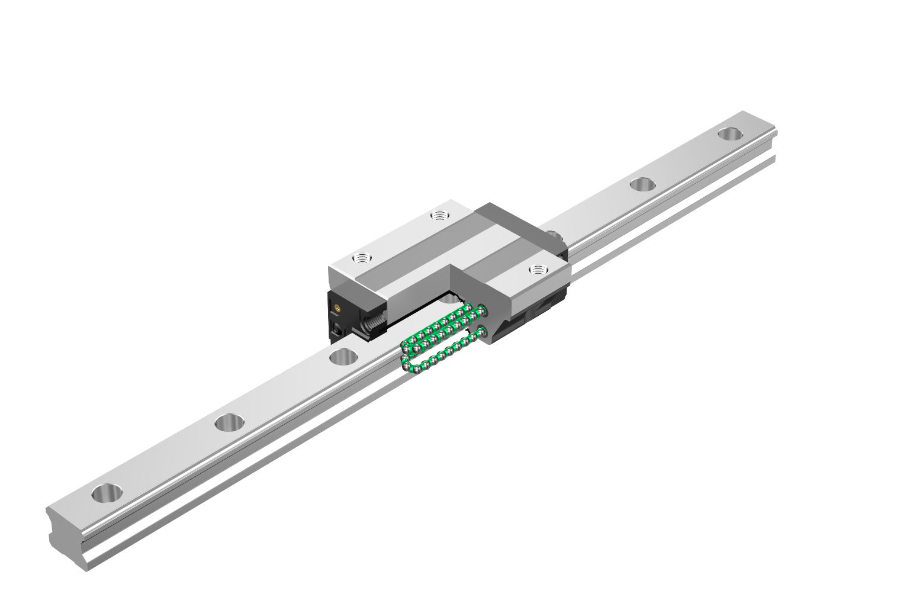

Hydraulic equipment solutions are not going out of vogue anytime soon as an always-expanding sector. Should your industrial company use hydraulic equipment in its manufacturing process, you must make a purchase of premium machinery.

Not every hydraulic hose and fittings is the same. With most other machines made up of different assembled parts, the quality of these components directly affects how the machine runs. Your hydraulic equipment follows the same principle. Although more costly products are not always of superior quality, the price might sometimes reflect better materials and features of a particular component.

Benefits of Investing in High-Quality Hydraulics

-

Durability of Equipment

If you are looking for high-quality equipment, you will want the machinery to be robust and well-built so that it lasts longer. No matter your sector, hydraulic equipment with a long lifetime could provide several advantages.

Although better quality hydraulic equipment could initially cost more, this can usually be offset later on as you won’t have to spend as much on repairs. Choosing a less expensive choice could appear to save you money, but a shorter lifetime could require your equipment to be replaced far sooner, more cost over time.

-

Reduced Upkeep

Investing in high-quality hydraulic equipment has another advantage: less upkeep. Besides a longer lifetime, you won’t have to halt manufacturing for repairs. Less expensive equipment could cause you to require ongoing machinery repairs when parts start to break. Your company will not wish to cope with higher labor expenses as well as manufacturing loss.

While high-quality hydraulic machinery will always gain from preventative maintenance, these machines might usually require less focus. This lets your employees concentrate on your output instead of looking after a malfunctioning machine. Time returned to your staff’s day allows them to be efficient and concentrate on their job.

-

Greater Efficiency

Quality parts help machines run better, aside from possible downtime and loss of production. Your company can function efficiently and successfully if your machines are working smoothly. Low-quality equipment can cause varnish and sludge growth; poor temperature changes can cause moisture in your hydraulic system by means of condensation. Investing in high-quality machinery helps you to reduce these hazards.

Your company can be certain that your production will stay on track with fully operating, top-grade tools.

-

Eco-friendly, Clean Tools

Regular repair and replacement of low-quality goods might produce more waste. Low-grade tools not only waste time and money but can create physical waste as well. Your sector will determine how this happens in many different ways. You want to keep all kinds of waste to a minimum, whether you’re tossing out items that don’t match your quality criteria because a machine isn’t operating properly, or you’re discarding the parts themselves when you replace them. High-quality hydraulic tools let you buy a clean, streamlined company.

Conclusion

Being a business owner, you wish for your staff to be content and complete their tasks. Usually, workers are far more productive when they like their current tasks. You can achieve it by giving your team the tools and machinery running smoothly.

Your staff members may sometimes feel annoyed with equipment either constantly broken or not functioning correctly. Giving staff members the tools they need to do their tasks shows you care about them and their experience on the job. High-quality hydraulic equipment not only maintains the efficiency of your machines but also reduces stress on your staff members and keeps them happy.